Why would I spend time pondering variable valve timing (VVT)? I do, because along with variable valve lift (VVL), it can make a big difference in overall vehicle performance. It is truly a brilliant technology. Let me tell you about it.

VVT/VVL Functions and Benefits

• Duration – how long the valves remain open (or closed)

• Valve lift – how much the valves open

• Timing – actual valve timing

VVT advances or retards cam/valve timing, while VVL changes valve duration and lift. Those three capabilities of VVT/VVL can help engines raise miles per gallon (MPG), increase horsepower and lower emissions.

VVT History

The history of VVT dates to the early 1900s. The first recorded use appeared on a 1903 Cadillac® Runabout, for which a variable valve mechanism patent was filed. However, it wasn't until the late 1970s and early 1980s that technology truly started to develop with companies like Alfa Romeo® and Nissan® pioneering it in production cars. The Alfa Romeo Spider 2000® was the first mass-produced vehicle to feature VVT in 1980. Later, Honda® significantly advanced the technology with their variable valve timing and lift electronic control (VTEC) system, making it a VVT major evolution milestone. Now, nearly all OEMs use VVT.

• Subaru® has active valve control system (AVCS)

• Nissan has continuous variable valve timing control system (CVVTCS)

• Hyundai®, Kia® and Volvo® have continuous variable valve timing (CVVT)

• GM® and Vauxhall® have dual continuous variable cam phasing (DCVCP)

• Ford® has twin independent variable camshaft timing (Ti-VCT

• BMW® has Valvetronic®

Most use the acronym VVT. They may all work slightly differently, but they all work toward producing the same goals.

Variable Valve Timing System: The Main Components

• Powertrain control module (PCM)

• Sensors – variable valve timing sensor, camshaft position sensor

• VVT camshaft adjuster consisting of stator, rotor, vanes and locking element

• Camshafts

• Solenoids and actuators

• Clean oil

VVT issues can occur when the valves don't open and close at the right times. This can cause problems with the engine's performance, fuel economy and more.

Symptoms include engine light, rough idle, decreased power, decreased fuel economy, engine noise and misfires.

Some of the symptom causes are debris in the oil that can clog the screen between the solenoid and the VVT pressure switch. The VVT solenoid may fail, causing mistimed valve openings. Damaged wiring, loose connections or corroded terminals can also prevent the VVT system from working properly.

Most systems depend on hydraulics to adjust timing. Oil is critically important to these systems working properly. Low, dirty or even the wrong oil weight can cause issues or damage.

A diagnostic trouble code (DTC) will set for most problems, even those caused by oil.

A common variable valve timing trouble code is P0011. This code indicates an "A" camshaft position timing over-advanced issue, usually signifying a problem with the variable valve timing system on Bank 1 of the engine. Other related codes may include P1009, P0010, P0023 and P0014, depending on the specific issue with the camshaft position and bank involved.

Key points about variable valve timing trouble codes:

Meaning:

These codes usually point towards a malfunction in the system that controls the timing of the engine valves, allowing for optimal performance based on driving conditions.

Common causes:

• Faulty variable valve timing solenoid (stuck open or closed)

• Low oil pressure affecting the VVT system

• Worn or damaged timing components

• Electrical issues with the VVT solenoid circuit

Symptoms:

• Check engine light illuminated

• Rough idle

• Decreased engine power

• Poor fuel economy

• Unusual engine noises

Below is a great case study to illustrate an efficient workflow for a VVT issue, not to mention a complimentary way to get real world help while learning these different systems. I copied this directly from a Snap-on® SureTrack® blog (suretrackblog.com), which is available free online.

Vehicle

2004 Honda Accord® EX 2.4L

Title

P1009, Replaced Camshaft Timing Oil Control Valve

Complaint

The customer states the check engine light is on.

Cause

Connected a Snap-on TRITON™ scan tool and found code P1009 – VTC Advance Malfunction. Performed an inspection of the engine oil level and condition and found the engine oil was at the proper level and was clean. Used the scan tool to clear the code, test drove the vehicle and found the code returned. Removed the camshaft timing oil control strainer, inspected for a restriction and found no faults.

Performed a visual inspection of the camshaft timing oil control valve wiring harness and found no faults. Disconnected the camshaft timing oil control valve harness connector, inspected the terminals and found no faults. Removed the camshaft timing oil control valve from the engine, visually inspected the valve and observed no obvious faults. Attached fused jumper wires to the camshaft timing oil control valve, supplied battery voltage and ground and found the camshaft timing oil control valve did not actuate. The results of these tests found that the camshaft timing oil control valve was faulty.

Correction

Replaced the camshaft timing oil control valve, cleared codes, performed a road test and verified the vehicle operated properly. The check engine light did not illuminate and fault codes did not return.

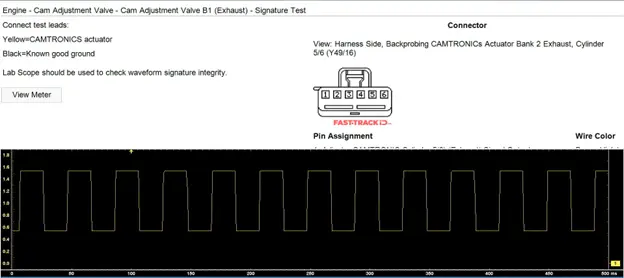

If this was a Mercedes-Benz® case study, it might have required another step using a tool with guided component tests like the Snap-on TRITON series. A cam adjustment valve test is available with current software. The test would verify the component is good or bad, a perfect way to prevent misdiagnosis.

It is amazing how much automotive engineers have elevated the performance and efficiency of modern engines with this brilliant technology. It makes me wonder how much more they can squeeze out of engines in the future.

Click here for more on this topic, and for so much more, visit Snap-on’s technical article pages.