The tyre pressure monitoring system (TPMS) of days gone by was to kick the tyre to check for a hard, pressurised tyre. Between that and a visual check, that was what we had, short of actually putting a tyre gauge to work. Modern day TPMS is a virtual tyre kick that has developed into a highly accurate safety device.

The very first TPMS vehicle was a 1986 Porsche® 959. In 1992, Renault® introduced the safety system in the Renault Laguna and Megane Scenic.

In the early 2000’s 14.4 million tyres contributed to 279 deaths due to tyre failures in the US. This triggered a law that mandated TPMS notify the driver when a tyre is below 25% with a warning light in all vehicles under 10,000 lbs (5 tons).

This law went into effect in the European Union and UK in 2009 which mandated that all new car models must be equipped with TPMS as standard from 2012. TPMS checks were subsequently added to the MOT checklist in January 2015, applying to any vehicle registered after 1st January 2012.

TPMS is designed to alert the driver to low tyre pressure while the vehicle is traveling as well as when it is stationary. Low pressure is responsible for many accidents and breakdowns. The possibility is greatly increased when a tyre has low pressure. Incorrect pressure also has a negative effect on fuel economy, emissions and tyre wear.

There are three methods for measuring tyre pressure:

1. A coded tyre valve with a unique identifier mounted within the load wheel.

2. A coded tyre valve with transmitter mounted externally from the road wheel.

3. An indirect system using output from the ABS wheel speed sensors.

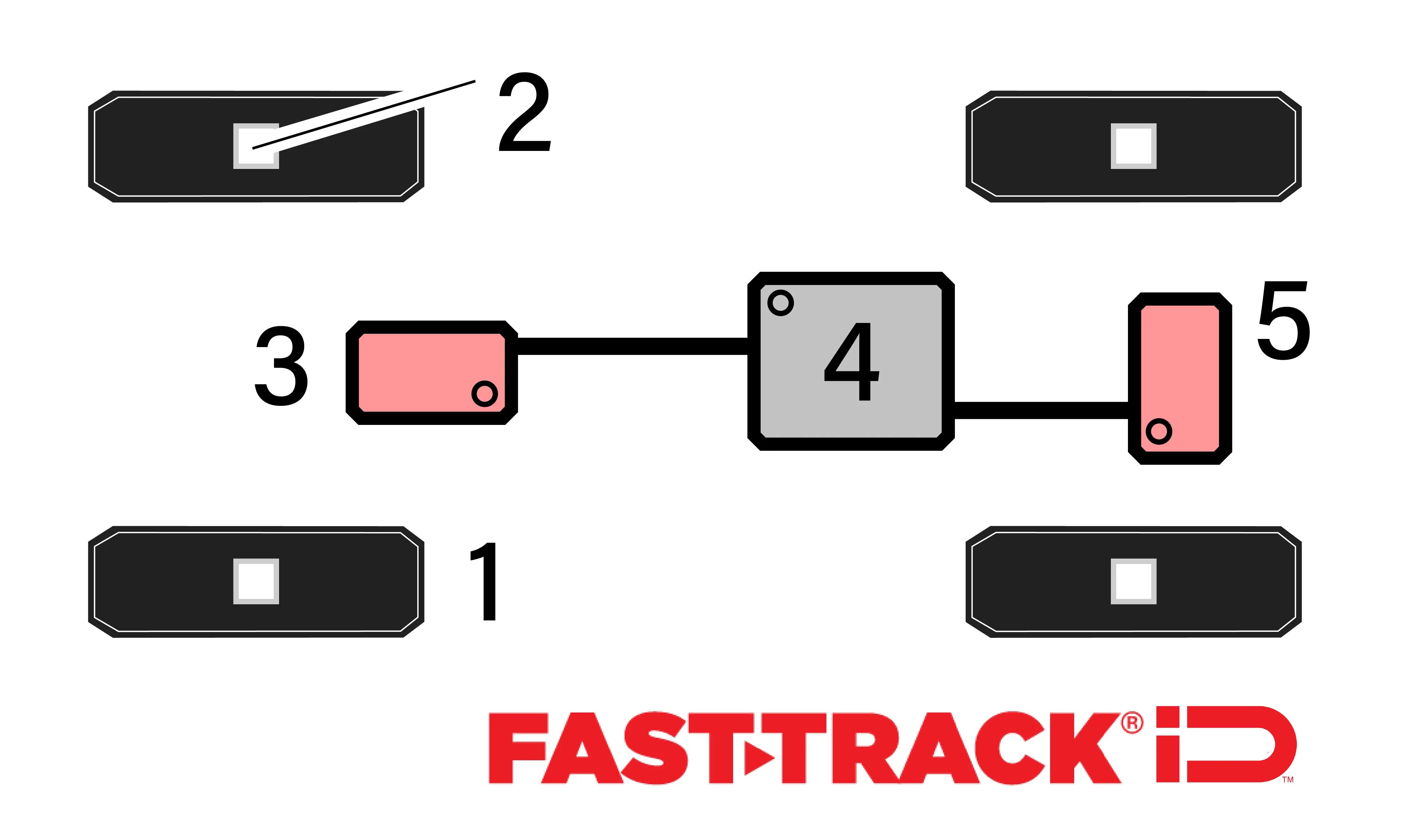

The diagram below shows an example of method No. 1, the coded valve mounted within the wheel.

1. Road wheel

2. Tyre valve

3. Radio frequency receiver

4. Body control module

5. Instrument panel

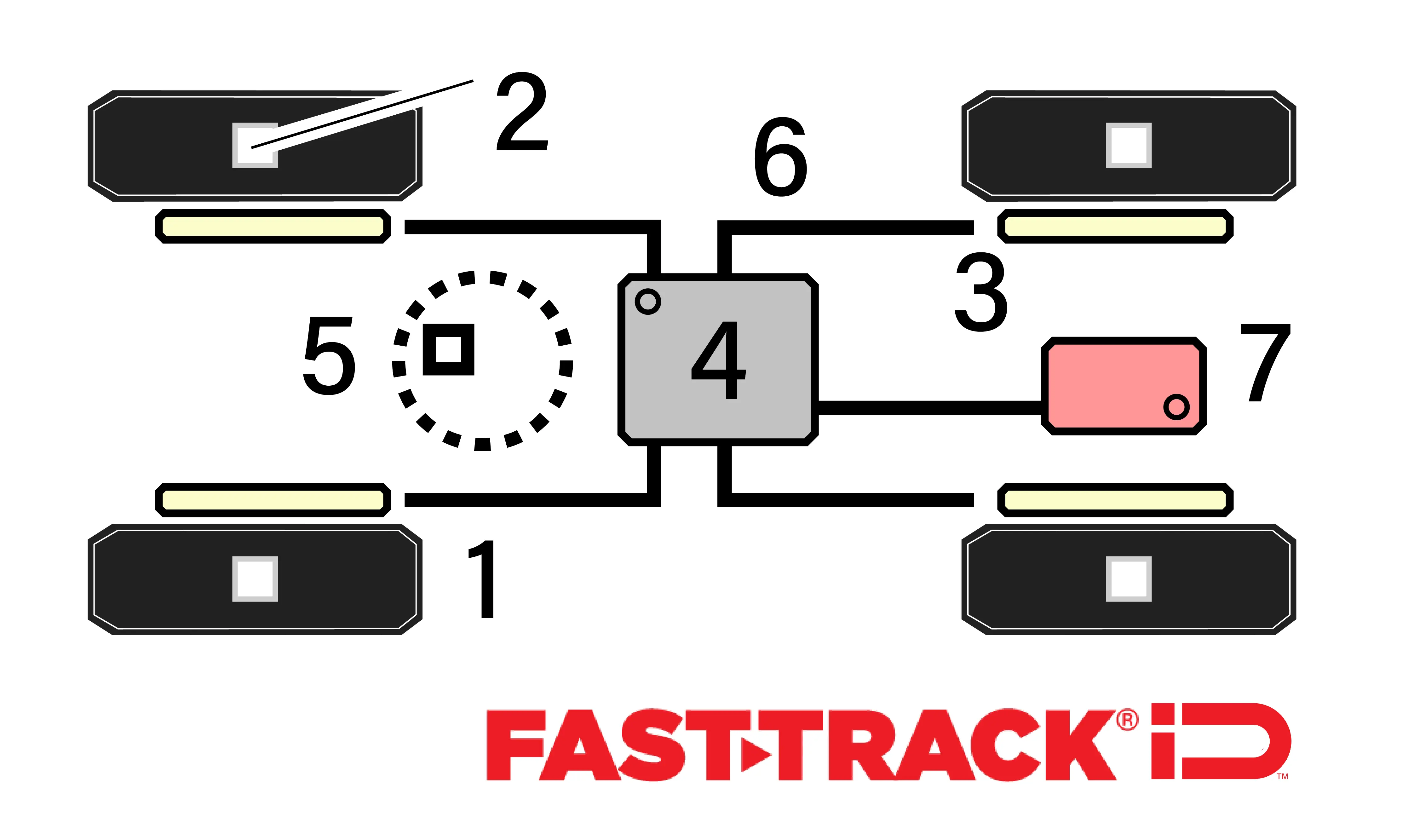

The diagram below shows an example of method No. 2, the coded tyre valve with an externally mounted transmitter.

1. Road wheel

2. Tyre valve

3. Transmitter antenna

4. Tyre pressure monitoring control module

5. Spare wheel

6. Instrument panel

Both methods use a radio frequency of 315 MHz or 433 MHz to relay pressure data to the control module. They also use a non-replaceable lithium-ion battery with a 7 to 10 year life span.

The third method uses wheel speed sensors to calculate tyre pressure. Low pressure results in a reduced tyre circumference, which will alter the wheel speed sensor. Overinflation will increase the circumference, which will show up in the wheel speed as well.

Once the TPMS sensors are replaced, they may need to be calibrated to read the correct tyre pressure based on the vehicle’s specification, depending on the OEM. Some vehicles have specific needs such as towing or high load, which will need the tyre pressure to be set higher.

There are some trouble codes that can appear that can help technicians identify issues including:

• Tyre pressure too low or too high

• Defective tyre pressure sensors

• Faulty TPMS control unit

• Faulty wiring

• TPMS reset needed

Some trouble codes include:

C2133 - No signal received from transmitter ID3

C2134 - No signal received from transmitter ID4

C2177 - Initialization not completed

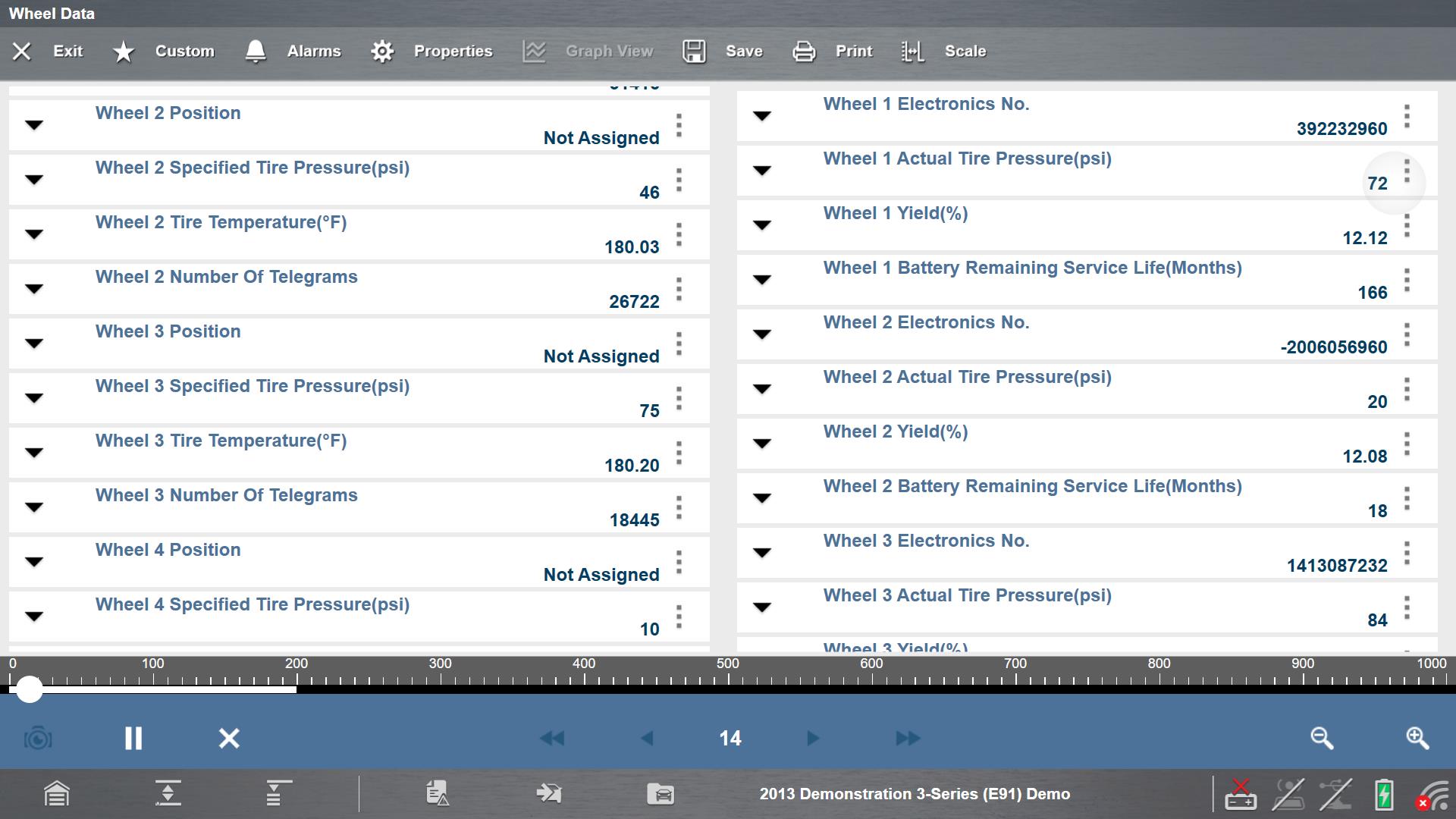

Furthermore, tyre pressure monitoring systems have data display available on many scan tools. It offers various data, depending on the OEM, such as air pressure, obviously, and maybe even tyre temperatures. Some list the registration ID, Vehicle speed, and sensor battery voltage. Insome cases might be included, too. In some cases, the remaining service life of the battery, measured in months, may also be shown.

Additionally, functional tests or special functions like tyre pressure adaption, manual procedures and right tyre position are available for certain OEMs.

Tyre pressure monitoring systems are definitely more accurate and safer than kicking the tyres, plus they will monitor the tyres at 70 MPH. A tyre kick at that speed might be a bit of a challenge!

Check out Snap-on TPMS Tire Pressure Monitoring Sensor here or speak to your local franchisee for the best deal on the tuck.